Dongfeng Cummins Engine Co., Lt is located in high-tech industrial development zone of Xiangyang, Hubei. It is a joint-ventured modern medium and heavy engine manufacturing company funded by Dongfeng Automobile and Cummins Corporation. The total registered capital is over 100 million dollars with total area of 270000m2. Number of employees are more than 2200.

The products include B, C, D, L, Z series Cummins engine that could meet the National Emission Standard V, VI and off-road National Emission Standard IV, engine capacity is 3.9L, 4.5L, 5.9L, 6.7L, 8.3L, 8.9L, 9.5L or 13L. The power coverage is 80-680 horsepower that widely used in light, medium, heavy trucks, middle and high ranking intercity coaches, large and medium public bus, engineering machinery, marine main and auxiliary equipment, generator set and etc.

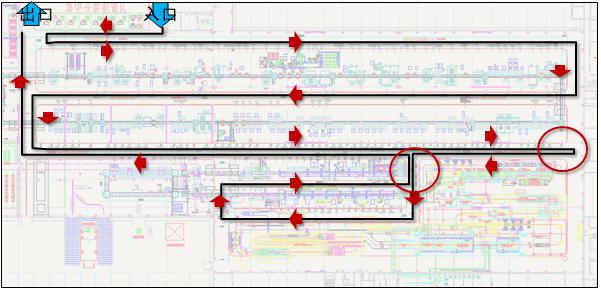

This project was started in September 2017 by Fablog. DCEC intended to establish a new APU line in east area inside the current factory to meet the demand of new production line capacity and sufficient mixed manufacture, improve logistics function level, achieve the advance of planning and logistics, reach Cummins standard.

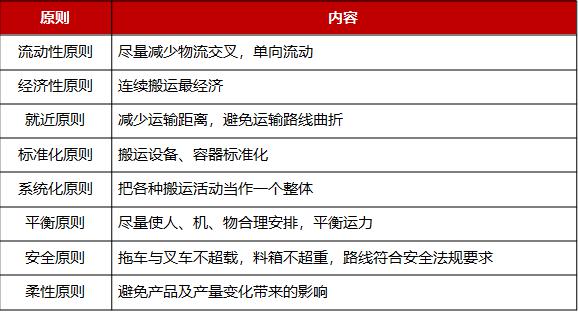

The project is based on Germany standard and had four steps including data analysis, concept planning, detail planning and project implementation. Fablog analyzed logistics management, production planning system, IT system, packaging container and 3PL, and then took them as key points in the follow-up planning.

Materials line feeding package was classified by inbound package type, size, and capacity. Package standard was made and special material shelf was designed and audit as well. Several options were provided according to DCEC current situation and limited conditions. Fablog estimated and compared difficulty, resource investment of the options and finally chose one option and determined assignment of responsibility inside and outside the factory, operation of lineside buffer inventory and resource planning for subsequent process. Furthermore, Fablog did detailed planning for assembly line delivery and line side logistics area, and raised requirement for equipment and line side.