The company

Siemens Transportation Systems – one of leading system houses of the train industry – received for the modernization of the Londoner regional railroads the largest order in company history until now. The project with a total volume of about 2,5 Mrd. EUR includes the delivery of 1.200 dares. On basis of the successful Desiro-Sequence Siemens developed vehicle system specially adapted to the British market in shortest time – the Desiro UK. The supply logistics and the gradually installation of the vehicles require a high effectiveness and transparency of all information and material flows between the single Siemens locations and even with regard to the suppliers – a large logistical challenge.

The task

The most important goal during the start phase of the project was to integrate the involved suppliers into a smooth functioning supply chain as quick as possible. The production of one dare per day meant to many suppliers a substantial increase of their delivery capacity. Furthermore various suppliers had to be integrated whose efficiency, punctual delivery and possible weaknesses were not known. To have all parts and kits available corresponding to the production process at the segments of the final assembly, the supply chain had to be checked for weaknesses and optimised in shortest time.

The solution

Together with a FabLog-Logistics-Adviser team a three point project was established:

First the approximately 500 suppliers – 30 system suppliers – had to be subjected by a systematic selection, to recognize on which areas of the delivery network the attention has to be focussed.

The second step contains the execution of the supplier audit and editing corresponding information for a logistical early-warning system which helps the Siemens-expeditors to control the supplying processes according to more efficiency.

Finally in the last project step measures for supplier stabilization and process optimization were carried out.

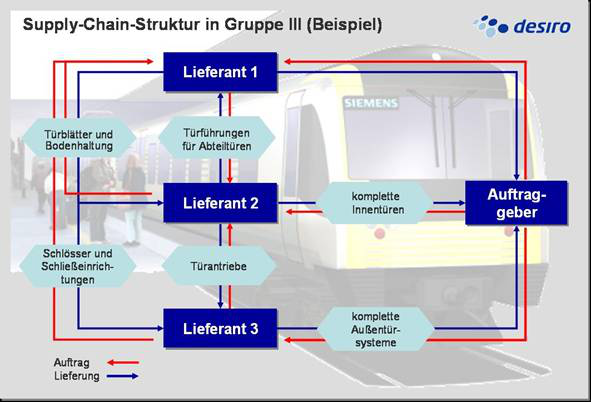

The documentation of the audits resulted in form of reports and comprehensive result descriptions. A special database matrix made it possible to grasp the audit data categorized and to recognize critical suppliers on the first sight. In the analysis’ result a quantitative and qualitative estimation of the delivery capacity from every certified supplier was put in addition. Surprising result: many of the suppliers are a part of a complex network which previously was not transparent for the buyer. According to the complexity of the Supply-Chain-Structure the companies could be incorporated into suitable categories to assign a corresponding higher meaning to certain suppliers in logistics disposition for the first time.