Fablog was invited by the world largest freight agent Kuehne + Nagel Limited-north Asia to audit BBAC MRA II factory production logistics service process which is the first project in China. For lack of operation experience, there were server problems inside the BBAC factory. Thus, BBAC third-party management division degraded Kuehne + Nagel service provider and required Kuehne + Nagel to have consultation and adjustment through fourth party.

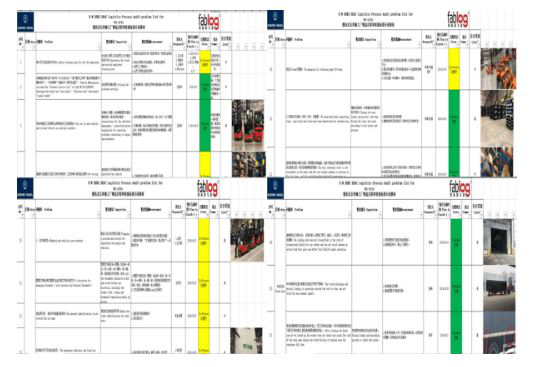

Fablog spend one month to audit BBAC project based on Germany VDA6.3 standards and provided a list with over 60 problems. More than 20 of them are directly affect the audit. Now the focus are announcement and training of VDA6.3 standards, formulation and study of key point rectification measures, orientation and methods in the further implementation process. The options will be admissive by Fablog, Kuehne + Nagel project team and BBAC, then handed to Kuehne + Nagel.

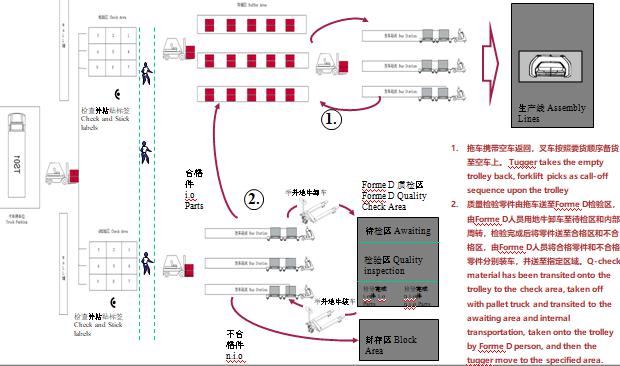

Key problems were analyzed with VDA standard during the audit. Such as height limitation of the products, division of vehicle and people in the regional distribution, technology vehicle management, appliance management, rationality of functional area layout, ergonomic in staff operation and HSE.