Arvato Service is an advanced third-party logistics provider(B2C call-centre warehouse) providing customized logistics service and solutions(including pre-sale, sale and after-sale value-added services). The target industries include: space transportation, automotive, media, tourism, telephone sales, FMCG, financial services and so on. Its China headquarters is located in Shanghai.

Over the years during its development in China, the business area of Arvato has been expanded a lot; and because of the excessive growth, the existing operating facilities and sites can not meet the increasing business needs(20 thousand delivery times at most a day). As a result, Arvato has to optimize its logistics system.

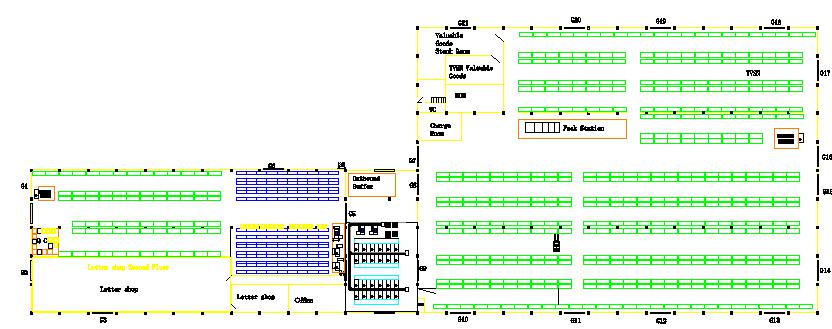

The main business of the B2C distribution center is to serve for Shanghai and its surrounding areas: including online orders, phone sales, phone shopping and other relative delivery of prize or gifts to optimize the ability of its logistics distribution center existing in Shanghai. The whole area of the warehouse is 5,109 square meters, with the customer's prize as well as high value items operated at the same time(cosmetics for example). Besides, this warehouse will start the operation of new phone sales project.

The logistics operation here mainly deals with some B2C businesses, this means the sorting strategy will be totally different with other logistics operations. Arvato is mainly in charge of the whole logistics business from the order online to delivered to users.

The main functions of the warehouse include: storage, sorting, packaging and distribution maintenance. The goods is mainly stored by boxes on standard pallet racking storage(ordinary boxes) and simple bracket storage(small boxes); the inner warehouse needs two kinds of storage environment conditions-high value goods stored in a separate isolation area of space, the prize stored(pallet storage) only in a ventilation area.

The core of logistics optimization includes:

Warehouse layout and materials flow optimization

Operation mode and business process optimization

Logistics equipment procurement and bidding management

WMS needs analysis and bidding management(including the connector with interconnected system)

Main problems customers encountered:

The low efficiency of dealing with B2C business small amount multiple batches orders(average one to two goods for each package); during sorting and packaging process, time is tight, and during operational process, a lot of errors occurred(usually the lead-time is short)

Besides, there are other problems including in B2C logistics:

High frequency return freight handling requirements

Exact match of different packaging materials and goods

Accurate screening to identify different shippers

Review different precision weightings

Seasonal fluctuations' impact on orders

Planning effect:

1. Spatial layout optimization

On the basis of historical data analysis of customers and field research, project team provided optimizing solution according to customer's low location use efficiency and unreasonable flow of inner materials. Planning contents include:

Clear functional area's distribution(high value/common goods/functional area)

Smooth material flow system(orderly and smooth operation flow of the whole warehouse)

Relatively independent visit channels(the operation flow and visit flow are separate)

Storage space and area optimization(reasonable layout of storage space and area)

2. Business process optimization

After deep analysis of B2C orders combined with goods' characteristics and all the possible sorting strategies, project team set a complete detailed operating mode and operation procedure and on the basis designed function needs analysis of information system. The contents include:

Analyze different orders' characteristics and make sorting strategy

Design standard inner warehouse operation procedure

Formulate flexible dealing process of special case

Information system needs analysis based on business process

3. Bidding management

Based on design of layout and process, system needs definition, project team formulated corresponding bidding documents of building construction, equipment selection and system development respectively, helped customers finish project management and complemented controlling. The contents include:

The construction bidding instructions(make complete CAD drawings)

Logistics equipment's bidding instructions(detailed instructions of the equipment parameters)

WMS system bidding instructions(the analysis of functional modules and demands)