Supor is China's leading kitchen appliance brand, China's largest and the world's second largest cookware R & D manufacturer, and the first listed company in China's cookware industry. The company has 5 major R & D and manufacturing bases: Hangzhou, Wuhan, Shaoxing, Yuhuan, Vietnam; it has more than 2,000 patented technologies, more than 10,000 employees and an annual production capacity of 100,000 pieces. In the past ten years, Supor's business has grown rapidly, with an average annual growth rate of more than 25%. Due to the growth of the business, Supor is stepping up the planning and construction of production bases.

Project work content:

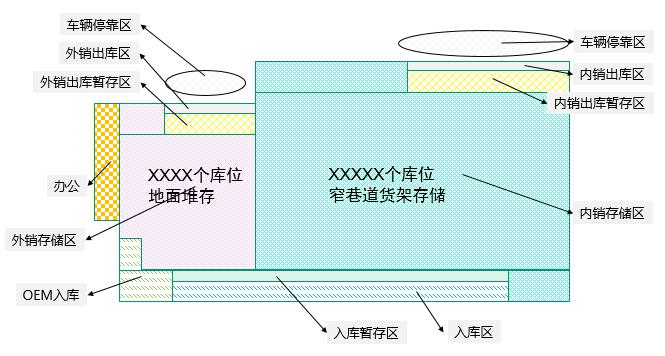

At the beginning of 2017, Fablog launched the finished product warehouse planning project of the Shaoxing base in Supor, which is mainly based on the manufacture of small appliances. The project is mainly aimed at the overall logistics planning after the finished product goes offline, including finished product going offline, storage in the warehouse and circulation, and finished product out of the warehouse. After rigorous on-site investigation, Fablog collected major data about product, order and warehouse.Through communication with management and on-site operators, Fablog clarified the future development direction, scale and actual project requirements. During the visit of the workshop and the existing finished product warehouse, Fablog clarified the actual layout and operation process of the site.

After that, Fablog project team analyzed and discussed the investigation, organized the field problem summary and gave detailed suggestions.Through the analysis of materials and data such as orders, warehousing, future development,clarifying the storage,picking and out-of-warehousing modes, Fablog finally determined the overall framework of the concept plan.The project team worked out two sets of conceptual schemes,mapped out the overall warehouse layout and explained the overall process and scheme equipment. Finally, the two schemes were compared in detail, and the comparison and selection opinions were given.